Understanding and Designing Your Masonry Oven

We have a wonderful opportunity before us: we can build an oven that is exactly the oven that we want. How rare is that? We buy used houses, prefabricated cars, and already landscaped gardens. This time we will make decisions from the ground up, and the resulting oven will stand for decades if not centuries.

That’s quite a responsibility.

This information sheet will explain how masonry ovens work and will outline what design choices we can make for practical and aesthetic purposes. Throughout, it will give a rough idea of cost. We can give more specific quotes after talking through the specifics of the design, the site, and other contextual issues.

How a masonry oven works

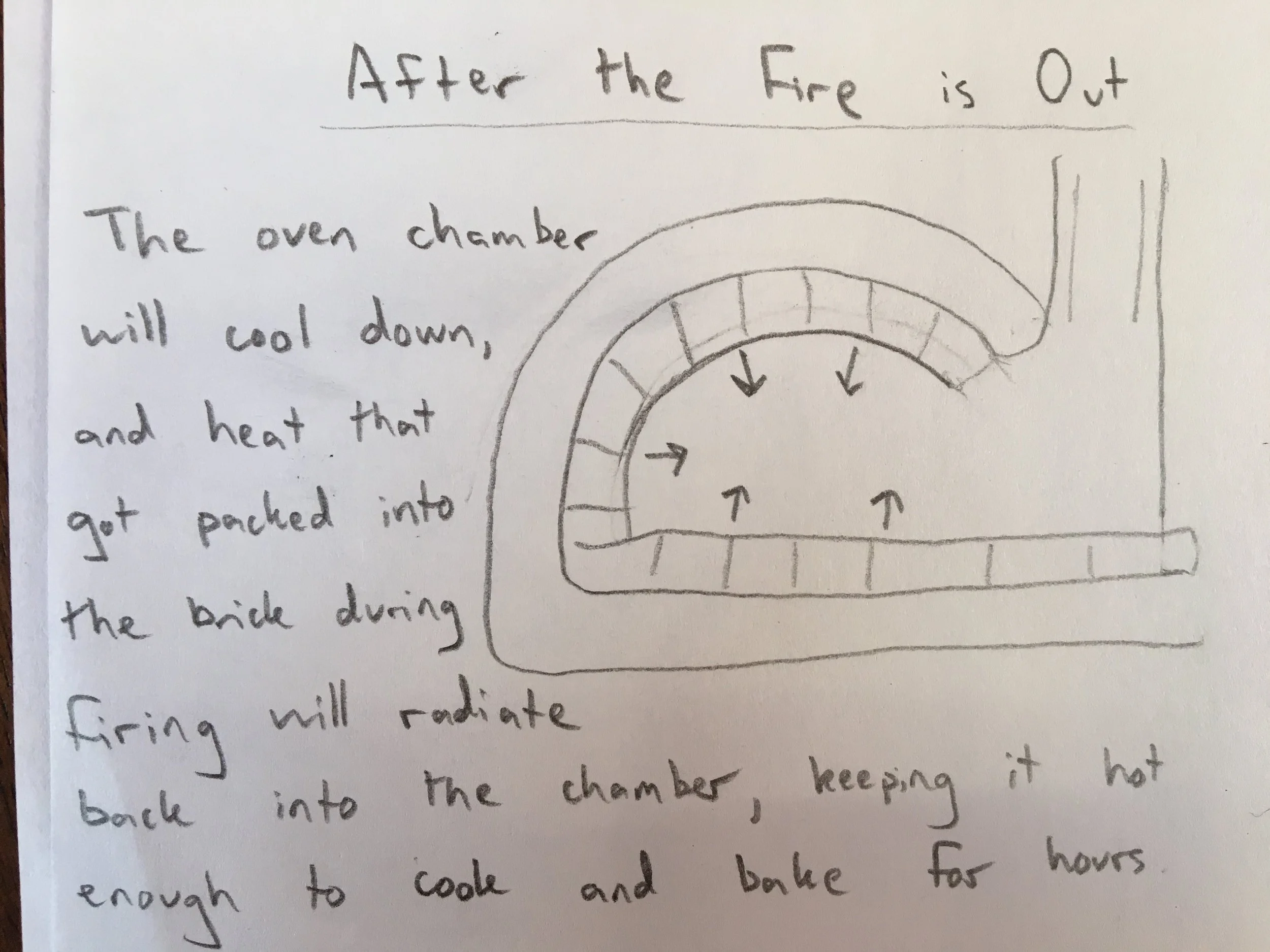

We call our masonry ovens direct-fired because we light our fire in the same chamber in which we will be cooking. As we burn the fire, the brick walls, hearth, and ceiling of the chamber begin to heat up. Heat looks for cold areas, so that heat will slowly travel deeper into the brick, one inch at a time, until it hits our insulating layer. We insulate our ovens with highly effective, refractory material, so the heat can only travel as far as the brick and won’t get out into the cold outside air. By the time you have fully fired your oven, the brick will be saturated with heat, perhaps at 500 or 600 degrees. Inside the oven chamber might be well over 1000 degrees.

That is the moment that we pull out what’s left of the fire. As the oven chamber slowly cools off, the hot brick gives back its heat. Think of all the heat that is stored in 4 inches of 500 degree brick! Enough to bake quite a few loaves of bread, not to mention chicken, veggies, baked beans, tofu…A well-fired oven will cool down very slowly over many hours because there is a constant supply of heat in the brick that is ready to drop into the oven chamber whenever the chamber drops below the heat of the brick (the physicists would say that the heat equilibrates).

Design choices, top down

Roof. In New England, we must either fight or cooperate with water and frost at every turn. Water degrades masonry, and frost splits it apart. We insist on putting roofs on our masonry ovens around here. A roofless oven in New England could last decades, but a roofed oven could last hundreds of years.

Questions: Would you like a roof that is separate from the oven? A separate roof will shelter you as well as the oven during a snowy-day-bake. Would you like to build the roof directly on the oven? A roof built on the oven will be lower profile.

Cost: A roof build directly on the roof will be cheaper because it has a smaller area and integrates with the oven structure. A separate roof needs its own support structure, which can add up fast.

Dome vs. Barrel Vault. A dome oven looks like one hemisphere of a globe or the top of the US Capitol building. A barrel vault looks like a wood barrel that’s split top down and then turn on its side, or like a round-topped tunnel quarried out of a hillside. Some oven-builders will only build domes, arguing that domes are far stronger than a barrel vault. They are right. A dome has infinite self-supporting arches, and every brick is supported from every side. A barrel vault, however, has three or four self-supporting arches in a series. The bricks are well supported in the arch but aren’t supported on every side. So should we only build domes? We don’t think so. Well constructed vault ceilings have been fixtures of buildings and ovens for hundreds of years, and the years have proved their durability. Any oven that is thousands of years old is a dome oven, but do you need an oven that will last 1000 years? Up to you. The upshot: a dome construction is best practice, but we have confidence that our barrel vaults will last decades if not hundreds of years with minimal maintenance.

Questions: Do you have an aesthetic preference for the dome vs. the barrel vault? Do you have a preference for a circular shaped hearth vs. a rectangular hearth when baking? Do you want to spend the extra money to build with best practice or are you comfortable, as we are, building a well-designed barrel vault?

Cost: Dome construction requires that each brick be cut at least three times. That means extra time, some wasted brick, and wear and tear on our tools. Depending on the size of the oven, a dome will cost between $750 and $1250 more than a barrel vault oven of the same size.

Barrel Vault

Dome Oven under construction

Thickness of Oven Walls and Hearth. You can imagine that an oven with 4” of brick will store less heat than an oven with 6” of brick. Once the fire is out, you will be able to bake and cook for longer in the 6” oven than the 4” oven. The downside is that you will need to fire the oven longer to heat all that extra 2” of brick. Pizzerias leave the fire in the oven while cooking their pizzas, so they don't need thick walls that retain heat after the fire. They would rather have a fast initial heat-up time . Bread bakeries, however, want to bake bread in the 350 to 500 degree range for hours without a live fire. They will gladly fire the oven for a few extra hours so that they will have steady, retained heat long after the last coal is pulled out.

Questions: What kind of cooking will you be doing? How do you want to balance the heat-up speed and the heat retention?

Cost: Thicker walls use more brick, but not significantly more. If you think you want thicker walls, you should have thicker walls. This is not something to compromise on.

Veneer. The most exciting and variable part of the oven is the veneer. What do you want the oven to look like on the outside? Do you want that classic pizzeria, boxy brick look? Or the southwestern, stucco? Or maybe a stone archway with stone details in the chimney?

Questions: When you picture your oven in your mind, what is the general feeling of the oven? Domineering, soft, impressive, underspoken? How will the oven fit in with your yard, your house, and your neighborhood? How much can you spend to make the veneer exactly how you want it?

Cost: A plaster finish is the most cost-effective way to finish an oven. We us lime plaster that is more durable and more beautiful than the Portland stucco, and can be lime-washed with different colors whenever you want. A brick veneer, depending on the amount of detail we add, is more expensive but doesn’t break the bank. The price increases more if we work with beautiful but pricey materials like granite or slate, or if we add custom details like wooden doors over the wood-storage area or building in lights.

This oven went with cheap, simple plaster that showed off the beautiful stone.

The veneer of this 1700's oven was pragmatic--brick with no unnecessary details. You may want to mimic this brick style by using old brick and lime plaster. Don't worry: we'll clean the mortar off the brick if you want.

Base and Counters. The base of the oven serves two purposes: 1) most importantly, it elevates the oven to working height and 2) it creates a storage area for wood, tools, or anything else you want to cram in. The base can be customized to a certain height, a certain shape, or with particular openings. The standard base will be a rectangle with an opening in the front and a an opening on the side or the back. Counterspace is a necessity when baking outside, but it is entirely optional whether you want to build the counters into the oven structure, build them seperately, or cobble together a collection of tables and stones that do the job. We go for the Yes, and… approach to counterspace at my house. We use every surface available: space that’s built into the oven, built separately, tables dragged over, and, of course, there’s always the ground...

Questions: How will the oven sit in its environment, and how do you picture the counterspace fitting into that environment? Will you be doing a lot of landscaping around the oven that could change the way the space feels? Do you know what counterspace you want, or would you prefer to start baking and then decide what counterspace you’d like?

Cost: We are happy to build counterspace if what you want is within our skill set, and we can find subcontractors to help with any construction that is beyond our expertise.

With a mind towards recycled materials, we used "urbanite" for the base of this clay/masonry hybrid oven. We found a few construction sites with busted up sidewalk, and with a little sweat we had ourselves a free and durable base.

The stone wall next to this oven ties in the stone from the oven, creates counterspace, creates a grill spot (for boiling bagels!), and defines the edge the of yard.

Foundation Slab. The oven needs to sit on a floating concrete slab that will be strong enough to withstand decades of frost heaves. If you already have a well-built pad, we are happy to build on top of that. If you want to make the roof separate from the oven, we may consider making the pad large enough so the oven and roof are sitting on the same pad.

Questions: Do you have a pad you want to use already? How does your roof choice influence the size of your pad?

Cost: The cost depends on the size of the pad and how easily we can prepare the site for the pad. The type of soil will determine how easily we can dig the the hole for the foundation and what kind of drainage we need to put in.

So what's the damage?

You can see that there are many variables that go into the price of an oven. Not only does the size affect the price, but every step of the way we will make decisions that affect the bottom line. Often time, our customers will build part of the oven (the foundation slab, the roof, the landscaping, etc.) to help lower their cost. When all is said and done, our home-sized ovens generally cost between $8000 and $12,000. We can build a beautiful and expert oven on the low end of that spectrum; on the high end, you will get more labor intensive details, a more involved roof or landscape, or use of expensive materials.